No Products in the Cart

Peak horsepower headlines sell parts—but street drivability sells confidence. If your RAM 2500/3500 feels lazy leaving a light, surges on grades, or runs hot when towing, the answer isn’t another peak number—it’s a healthier torque curve, earlier spool, and controlled EGTs. In this guide, we’ll show how dyno data (paired with short road logs) translates into a truck that’s calmer in traffic and stronger on Utah’s long climbs. The examples below are patterns we see every week. Your pick up truck’s exact numbers will vary with altitude, tires/gear, tune, and load.

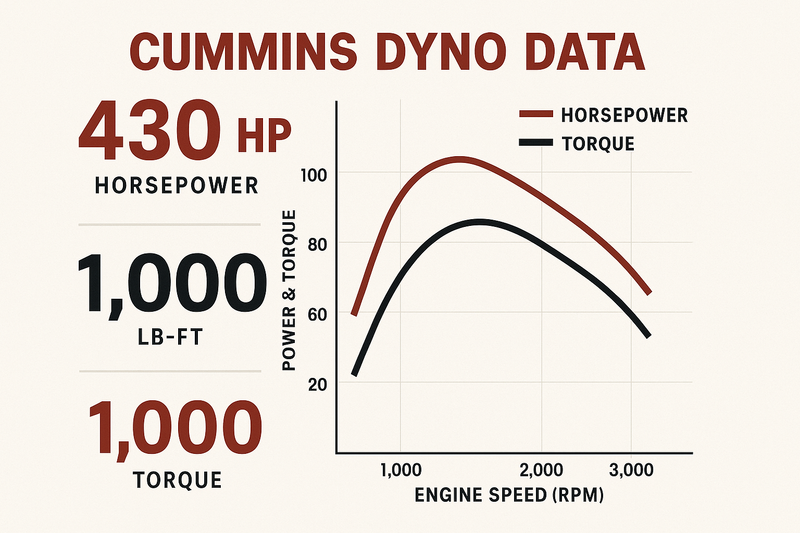

Dyno sheets are more than a top-right corner horsepower brag. For real-world trucks we care about:

Torque curve shape: A broad, flat torque plateau (starting earlier) beats a spiky peak that arrives late. It’s the difference between smooth merges and hunting gears.

Spool RPM: The RPM where boost becomes useful. For tow rigs, earlier spool = easier launches, less smoke, lower EGTs.

Transient response: How quickly boost and fueling stabilize after throttle changes. Good transients feel calm and predictable, not “on/off.”

Other helpful signals:

Boost-to-drive (EMP) relationship: We want healthy boost without trapping drive pressure—especially on VGT trucks under tow.

EGT trends: Instant spikes we can live with; sustained high EGTs we cannot.

Truck: 6.7L Cummins, RAM 2500, daily driver + occasional 8k trailer

Baseline: Stock VGT, stock injectors, basic tune, tired boots/clamps

Goal: Quicker spool, less tip-in haze, cooler grades—without losing engine braking

Before (representative pattern):

Torque rise starts ~1,900 RPM; peak torque hits hard ~2,400–2,600 RPM.

Tip-in haze and a small surge on steady throttle.

EGT creeps to uncomfortable levels on long 5–6% grades.

Changes made:

Charge system sealed (fresh boots/clamps)

Intercooler upgrade with lower pressure drop

VGT calibration for softer vane clamp off-idle and smoother midrange transitions

Smoke limiter tightened at low RPM; boost ramp cleaned up

After (representative pattern):

Torque comes in ~1,600–1,700 RPM and holds flatter to ~2,800 RPM.

Tip-in is clean; surge is gone.

EGT is lower at the same road load; downshifts happen less often.

How it feels on the street

Easier backing and hill starts—no “wait… now GO” lurch.

Steady throttle on I-215 feels planted.

Grade pulls are calmer; you can choose to downshift rather than being forced.

Why it worked

We didn’t chase a huge peak; we moved the useful torque into the RPM you actually drive and improved charge-air health so the tune could be honest.

Truck: 5.9L Cummins, RAM 3500, frequent 11–12k toy hauler, summer canyon trips

Baseline: Small fixed-geometry turbo, conservative tune, stock intercooler

Goal: Cooler sustained EGTs on climbs; keep launches manageable with the trailer

Before (representative pattern):

Quick initial spool but EGT stacks under sustained load.

Torque nose-dives as heat builds; driver sees repeated downshifts.

Changes made:

Properly sized wastegated turbo with freer hot side

High-efficiency intercooler and reinforced charge pipes

Tow-minded tune: gentler fuel ramp, EMP-aware boost target, timing for heat control

Fuel supply pressure monitoring added

After (representative pattern):

Spool remains acceptable for trailer launches.

Torque carries longer through the midrange.

Sustained EGT drops significantly at the same towing speed and grade.

How it feels on the street

Less gear hunting; the truck “breathes” on long pulls.

Driver focuses on the lane, not the gauge.

Brakes feel better on descents because the driver isn’t chasing momentum with throttle.

Why it worked

We traded a touch of ultra-early snap for repeatable airflow and cooler temps where the truck actually lives—on grade, at load.

A pretty dyno curve can hide a thermal problem. We always correlate power with EGT and (when equipped) EMP:

If power climbs but EGT climbs faster and stays high, you’re paying in heat. On a tow rig, that’s a no-go.

If boost is high but EMP is higher for long stretches, you’re stressing the turbo/engine. That’s a mapping or sizing fix, not a badge of honor.

If the midrange torque looks great but the truck surges, check boost ramp rate, leaks, and smoke limiters; the graphs should match the feel.

Rule of thumb: We’d rather deliver 10–20 lb-ft less at peak if it means a cooler, flatter curve and earlier spool you can count on in July heat.

Earlier plateau → smoother shifts: Transmission doesn’t hunt because torque is already available where the converter and gearing like to live.

Clean tip-in → better manners: Backing a trailer or merging at low RPM is drama-free; no haze or lurch.

Flatter midrange → calmer grades: You can settle into a gear and hold speed without riding the throttle.

Lower sustained EGT → confidence: You’ll still see heat spikes, but they come down instead of ratcheting up.

If your printout shows big peak numbers but the truck feels worse, try this simple triage:

Check the air path: Any boost leaks or tired clamps will murder spool and stability.

Review the intercooler: High pressure drop = hot charge temps = fake “power” that turns into heat under load.

Revisit VGT or wastegate control:

VGT: Too much low-RPM vane clamp → high EMP, smoky launches.

Wastegate: Opens too early → soft midrange; too late → overspeed/heat.

Tighten smoke limiters: Keep air ahead of fuel below ~1,800–2,000 RPM.

Confirm fuel supply pressure: Starving the rail creates inconsistent torque and dirty transients.

Retest on the dyno with a short log: One ramp run and one short steady-state hold tell the real story.

Pro tip: Compare ramp runs (accelerating) to a short steady-state hold (fixed RPM/load). If the ramp looks fine but the steady-state overheats, you’ve got a sustained-load airflow/EMP issue to solve.

A smart session includes:

Pre-run inspection: Charge system smoke test, actuator/wastegate check, filter status

Two dyno traces: A clean ramp run + a short steady-state hold

Quick log review: Boost, EGT, and (if available) EMP or fuel supply pressure

Action plan: Keep as-is, recalibrate, or pair with an intercooler/turbo that matches your use case

Typical time: ~90 minutes for baseline + consult (plan more if we’re sealing leaks or doing calibration changes).

Goal: Not a bigger number—a better-driving truck that tows confidently and stays cool.

Book a Same-Week Baseline Dyno

We’ll translate your graph into real-world changes you can feel tomorrow. Financing available for larger upgrade packages.

Because you don’t live at peak. Street and tow driving happen in the low-to-mid range, where torque curve shape and spool timing matter more than a single number at redline.

Yes, when done smart: good airflow, reasonable ramp rates, and short steady-state holds. We watch EGTs closely and stop a pull if temps climb beyond safe limits.

Often, yes. With better charge-air efficiency, cleaner boost ramp, and EMP-aware targets, we can hold the same usable torque (or more) while reducing sustained EGT on grades.